Various options for exterior surface treatments are available including stucco, paint, and numerous façade materials.

By changing features as simple as colour schemes and wall textures, very attractive and different appearances can be achieved.

Designing with colours can completely alter the look of a building, creating a special corporate image and/or adding that

personal touch to a home, or even an office. A broad spectrum of textures can also enhance a building’s image.

The colour of MEGA AAC products is shell white to grey white. As a result of the effects of storage, variations in raw

materials and the climate, variations in appearance may occur. Pores of different size at the surface are an inherent

characteristic of autoclaved aerated concrete (AAC) and are not considered defects in the quality of the product.

Coatings for MEGA AAC Blocks are readily available in unlimited colour possibilities. They are economical to apply with a

brush, sprayer, or roller depending on the specific application. Two types of patching mortar, specifically designed to

be compatible with AAC, are currently available to repair damaged areas prior to coating application. The severity of the

damage dictates which mortar should be used.

Painted Stucco

Exterior coatings manufactured for AAC are designed to be physically compatible with MEGA AAC products. Lightweight Portland

cement stuccos comparable in strength and density are recommended to assure long-term bonding and crack resistance. Additionally,

lightweight stuccos are polymer modified to provide enhanced bonding and workability. While lightweight stuccos are highly vapor

permeable and thereby assure rapid structural drying, they are also completely hydrophobic and will not allow water penetration.

AAC coatings are subject to high thermal tension. Therefore, any coatings used must have permanent high elasticity.

For MEGA AAC Blocks, exterior lightweight stucco is usually applied in a single coat at a minimum thickness of 8mm, following the

manufacturer’s recommendations. A texture coat of 3.5mm is then applied to the hardened surface. Lightweight stuccos are available

in numerous textures including a grooved, pebbled or typical sand finish variety. Once the textured stucco has set, apply two coats

of vapor permeable masonry paint. Any paint must be vapor permeable to allow moisture inside the block to escape.

Panels with mortared joints must be treated prior to the application of any surface coating. The panel joints are coated with a thin

layer of a cement-based compound. Embedded into the cement- based compound along the panel joint is an alkaline resistant fiberglass mesh.

A cement-based compound basecoat is applied over the entire surface at a minimum thickness of 3.5 to 5 mm. Immediately after the basecoat dries

(normally within one hour), skip trowel a light texture onto the basecoat. Once the textured basecoat has set, apply two coats of vapor

permeable masonry paint.

Panels with mortared joints must be treated prior to the application of any surface coating. The panel joints are coated with a thin layer

of a cement-based compound. Embedded into the cement- based compound along the panel joint is an alkaline resistant fiberglass mesh. A cement-based

compound basecoat is applied over the entire surface at a minimum thickness of 3.5 to 5 mm. Immediately after the basecoat dries (normally

within one hour), skip trowel a light texture onto the basecoat. Once the textured basecoat has set, apply two coats of vapor permeable masonry paint.

Paint

If desired, paint can be directly applied to unmortared panels which have tongue and groove profiles and chamfered corners. Paint used for

this application must reliably seal the slight surface irregularities of the panels. For this purpose, acrylic coatings with a higher filling

capacity than is customary with ordinary paints must be used. These polymeric coatings are typically applied in two coats to achieve a mini- mum

of 1 mm total thickness.

While paint can be directly applied to MEGA AAC walls, extreme care in joint preparation is required to achieve an acceptable appearance. The

joints in an MEGA AAC mortared wall are much thinner than in conventional masonry construction and therefore are more likely to reveal minor

imperfections. Even with the acrylic coatings noted above, joints may be visible. For applications where appearance is not a dominant consideration,

such as industrial buildings or garages, applying paint directly to an MEGA AAC wall can be an inexpensive and time-saving alternative. Any paint that

is used must be vapor permeable to allow moisture inside the block to escape.

Façades

The use of ventilated façades as an exterior surface treatment is very appropriate from a humidity and thermal point of view. Therefore, various façades

such as wood shakes, brick, stone, metal siding, vinyl siding and cementitious panels can be utilized. A furring strip substructure is advantageous since

it allows back ventilation. The furring strips are best attached to MEGA using AAC fasteners. Install all external materials per the specific manufacturer’s

recommendations. Typical waterproofing details including weep holes, flashing, lapping, connections and membranes should be incorporated in order to achieve

the desired weather tight construction.

Joint Treatment

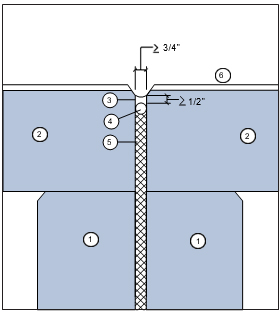

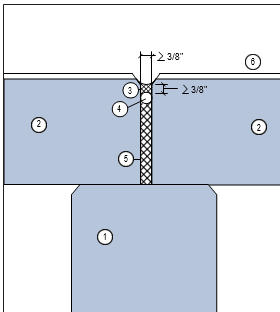

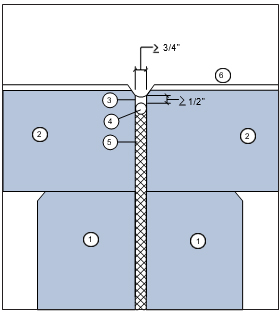

Listed below are three basic types of joints, classified according to application, requirements and orientation. In any case, the horizontal and vertical

joints in MEGA AAC walls must be weather tight. Suggested details are shown. Other options may be suitable depending on the project requirements. All materials

must be compatible with AAC

Ceramic Tiles

Ceramic tiles are not suitable weather protection when applied directly on MEGA AAC exterior walls because of the varied thermal conductivity of ceramics as compared to AAC. In addition, the difference in diffusion-inhibiting properties of ceramic surfaces which cause considerable tension, usually leads to loosening or cracking and finally to the destruction of the ceramic surface.